It seems we're in a phase where the term EMS does really cover what the companies we think of as electronics manufacturing service providers actually do. The offering has become so broad that the words 'electronic' and 'manufacturing' are just too restrictive. If we are to embark on a search for a new name for this industry then we first have to consider what it did when EMS seemed like the right term and what it actually does now.

The EMS industry started around 40 years ago and was very different to the 450 billion dollar industry we know today. It was contract manufacturing in its purest form. A vendor received a package of parts and build instructions, they followed those instructions and delivered the module, or perhaps product, back to their client. Inevitably the industry grew from there to be something much more holistic, providing purchasing leverage, design support and many other manufacturing and logistics services. Now we see an extremely broad offering and we see those vendors taking part in everything from innovation to end of life management.

From the original term EMS, only the word service seems applicable. The word 'electronic' seems too restrictive, as we see these huge manufacturing and fulfilment companies branch out into areas where the electronics element is at best minimal, and in some case non existent. Add to this the demands of certain sectors like wearables or medical electronics and it is easy to see a world where electronic content is not a requirement for these outsourced vendors participation. The next word is 'manufacturing', initially at the very core of what the industry was about. In fact initially the industry was mostly about PCBA (Printed Circuit Board Assembly) and the term CEM (Contract Electronic Manufacturer) was a widely used alternative. Now the entire product life cycle can be impacted upon by, or entirely outsourced to, these vendors and the word manufacturing does not even come close to describing what they do. The last word, 'service', was always the most important one for me. This is at the very core of the business model and the development of the industry and remains the key differentiator between these companies and the brands they serve.

We now have an industry that creates value for their customers by taking an innovation and delivering it to end-users wherever they need it. In its purest and most complete form, this service can be the entire manufacturing fulfillment process, leaving the brand, or IP (Intellectual Property) owner with only innovation and sales and marketing to worry about.

This rich service offering covers many elements.

At the start it means design. Taking a product from an innovation through prototype to something that can be manufactured in volume, worldwide, reliably, with a degree of mass customisation and to a quality and reliability level that suits the market and meets the demands of regulatory requirements. This requires very deep and broad design knowledge and resources, with an understanding of the issues that separate one industry from another. For example the design team that work on a high volume consumer product may not have the skills or experience to develop a product for the military or aerospace industry with its differing requirements of product life and reliability.

Next take the logistics around the fulfilment of a product. The consumer has been allowed, and in fact encouraged, to become more and more demanding. They expect product ramps to be fast, they expect delivery to occur quickly. And increasingly often they are demanding a level of customisation, or build to order in their products. This means that the logistical elements of the supply chain have become more complex, yet are expected to perform more consistently and more efficiently. Add to this the mitigation of disruption due to unforeseen circumstances like natural disasters and clearly this element of the process has become ever more complex. This is what we currently refer to as the supply chain. A term that previously looked quite dull, but has recently somehow become sexy...

Tacked onto the supply chain are all of the post delivery, or 'after market' services, like spare parts, recall management, product repair and end of life issues, like recycling or disposal. This is an industry in itself, yet one that has constantly been the target of, and a challenge to these vendors.

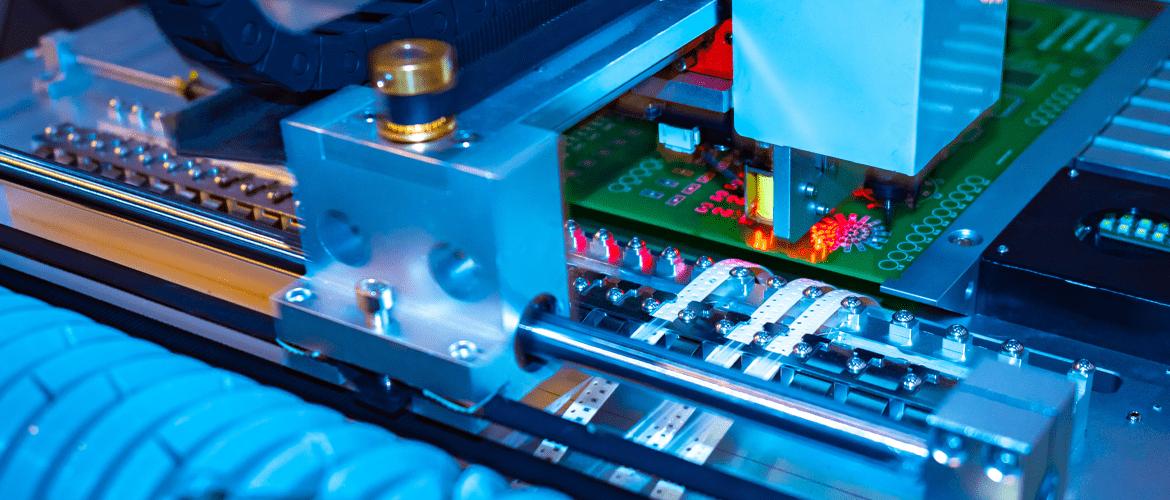

And let's not forget manufacturing, after all this is where it all began and what these companies have the greatest investment in. In all cases most of the workforce at these companies are involved in making stuff. And whilst they seem to want to shy away from the word manufacturing, this is the area they can be most proud of, they are really really good at it! After years of aggressive competition and growth the industry has done a great job at driving down the cost of manufacturing, whilst driving up quality, yield and reliability.

Manufacturing excellence has operated hand in hand with cost saving measures, often under the banner of 'lean' principles to create an environment close to optimal for the assembly of goods. Don't forget this manufacturing is not just electronic. Many companies have invested in metal, plastics and other manufacturing processes to ensure they can vertically integrate as much of the process as possible, win as much as the business as possible, control as much of the supply chain as possible, and ultimately offer as much value as possible.

We have a really sophisticated industry now, with a really sophisticated offering, and quite frankly it has grown out of its original name. To be honest so have their customers. They are not really the OEMs (Original Equipment Manufacturers) we once called them.

In this new world order we have companies that innovate and companies that deliver our products, and they are mostly two different enterprises. They have very different skill sets, very different resources, and very different business models. And for me the world, and the consumer, is better off for this new order. Products are better, they come to market fast, they are more reliable, and perhaps most importantly they are cheaper.

For me the companies that innovate and market the products are the 'brands', and those that do everything else are the product fulfillers. Product Fulfilment may not be the most exciting name for an industry, but it is what they do. Terms around EMS have been offered, like Integrated Manufacturing Services (IMI) or Global Manufacturing Solutions, but for me they are just a variation on the original term.

It's time to rename an industry and to redefine the relationship it has with its customer, perhaps by doing this it can also redefine the value it provides, which I am certain is greater than the margin it is allowed.

The 'Product Fulfilment' industry is the industry that the 'Brands' want and need.

Sign up for our blog

Stay up-to-date on the latest in manufacturing trends, insights and best practices.