Increase Agility

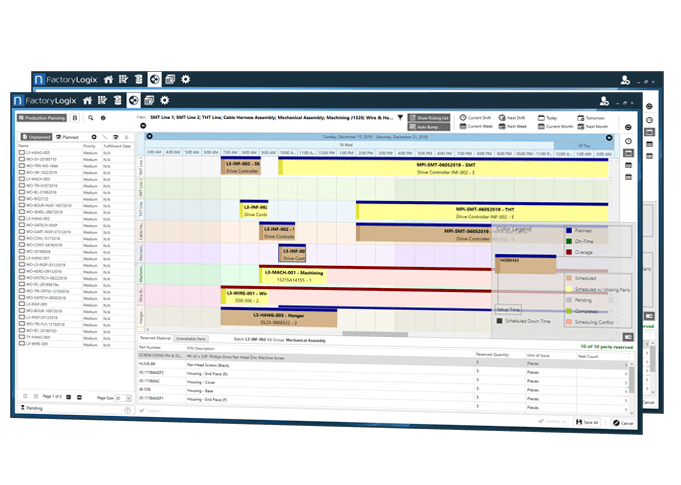

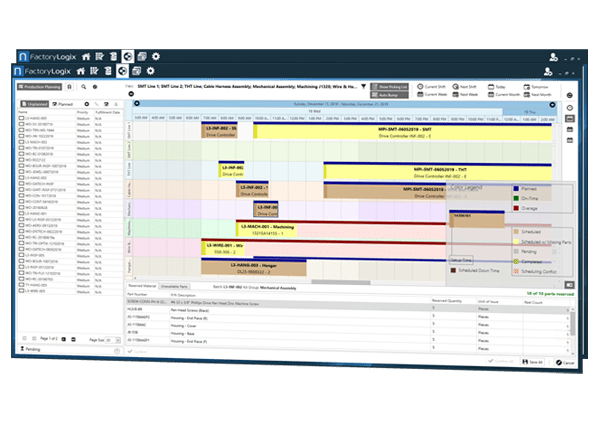

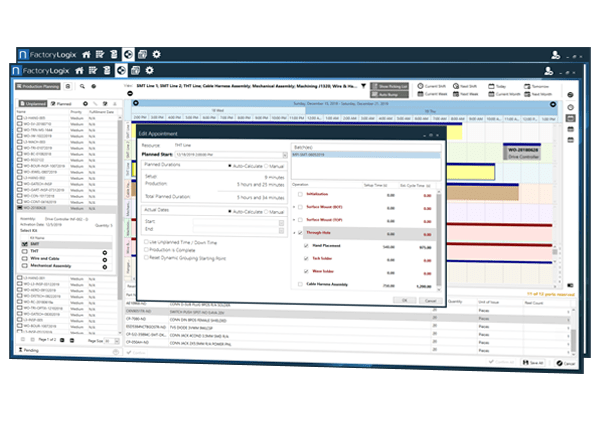

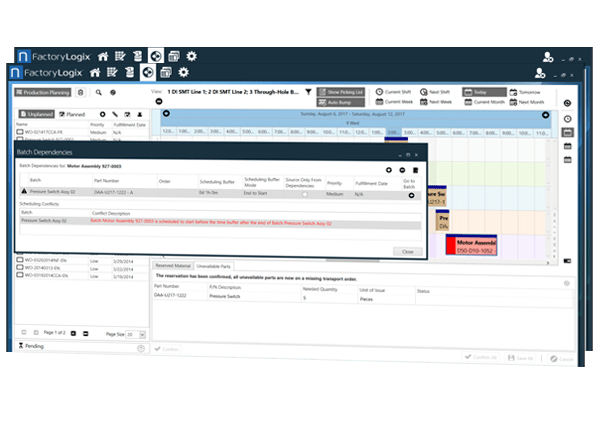

Only FactoryLogix includes the features and controls required for optimized high-mix Industry 4.0.

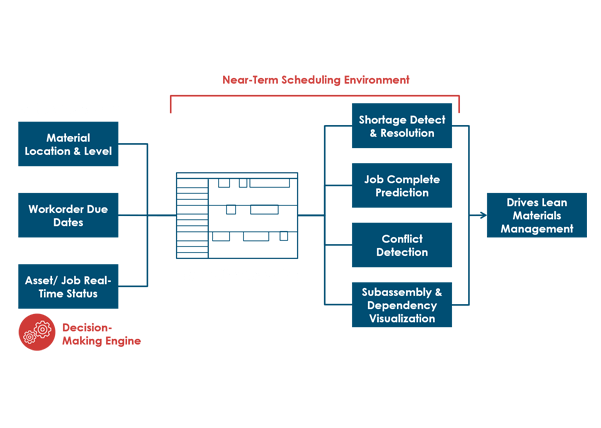

Increase Optimization

Replace obsolete long-term simulation with near-time resource-driven optimization.

Reduce Risk and Waste

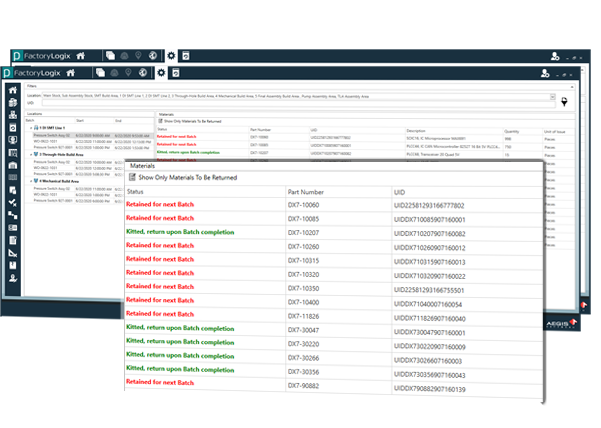

Visibility and control from our manufacturing production scheduling and adaptive planning software provides assurance of timely completion, avoiding pitfalls.

Successfully Respond to Changing Production Demands with Real-Time Visibility to Factory-Wide Materials, Jobs, and Assets

Improve High-Mix Throughput

Eliminate Bottlenecks

Reduce Inventory Costs

Meet Delivery Schedules

Optimize Equipment Usage

Improve Profitability

Some other clients we’ve helped