Human 4.0 Realized

By implementing augmented reality software in manufacturing operations, manual operators are now a seamless part of the digital factory, with vastly enhanced performance and flexibility as compared to traditional practices.

Flexibility & Learning Curves

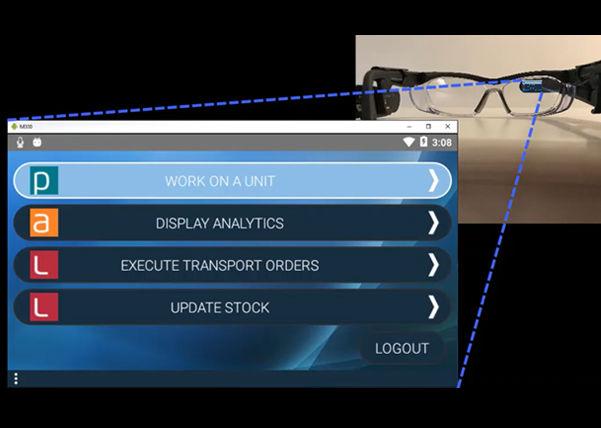

Operators with FactoryOptix become the most flexible manufacturing asset, moving seamlessly from job to job, role to role, without sacrifice of performance in terms of learning curve.

Enhanced Skills

Instructions and reference materials within AR software bring natural on the job training for operators who can increase and develop their skills without burdening existing specialists.

Mobilize Your Workforce and Get the Most Out of Your Human 4.0 Assets, Your Team

Improve Operator Satisfaction

Increase Flexibility

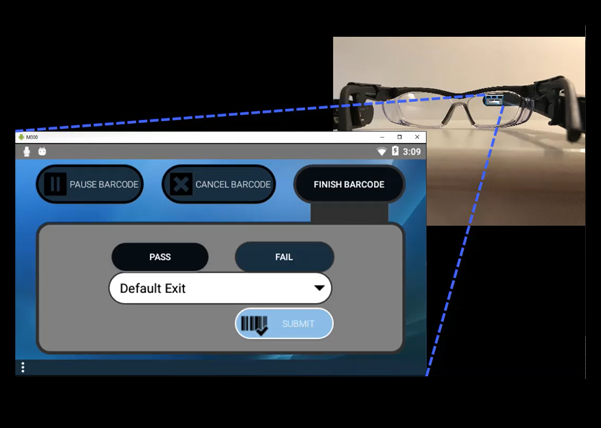

Enhance Quality

Promote Agility

Reduce Costs

Enhance Productivity

Some other clients we’ve helped