Accelerate & Simplify Production Launches

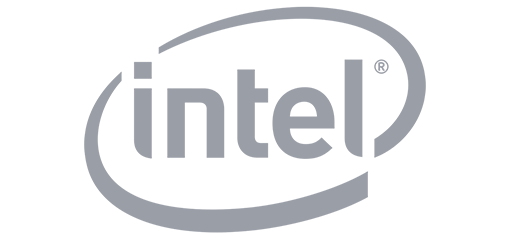

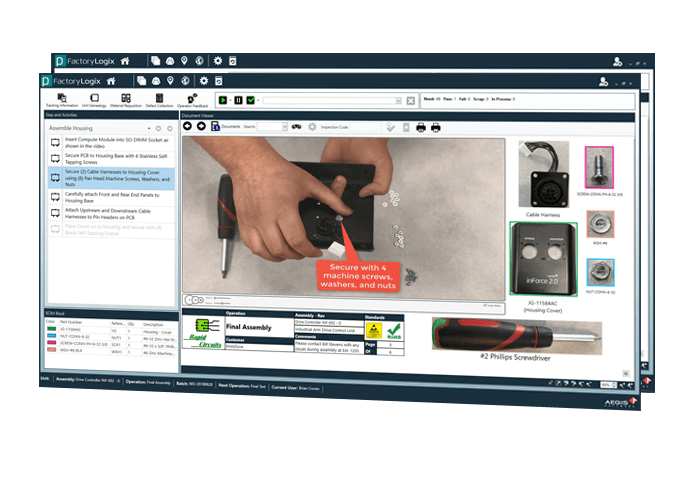

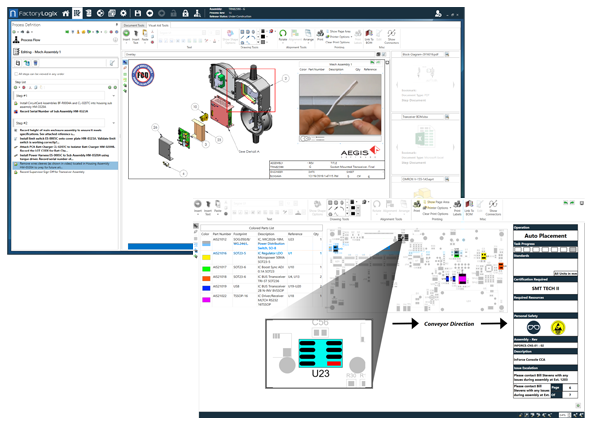

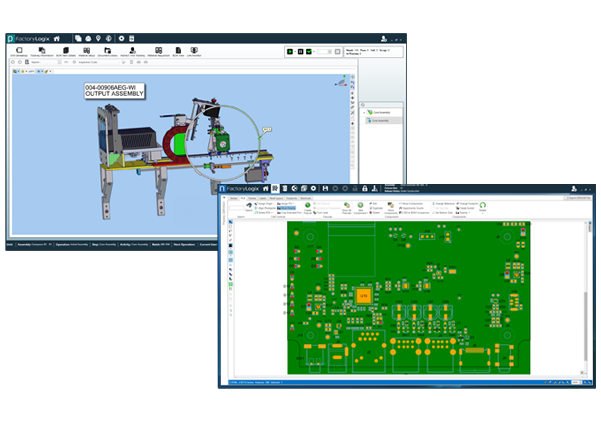

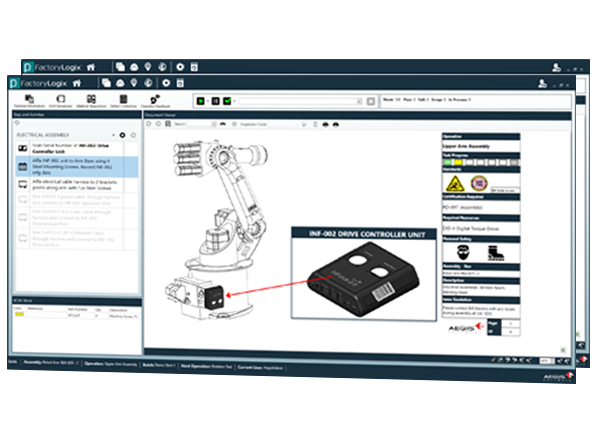

Eliminate mistakes, expedite, and simplify creation of everything needed to begin production, including BOM and CAD cleaning, production route and quality design, and visual work instructions.

Drive New Business Opportunities

Our manufacturing engineering software offers all the capabilities you need to ensure you improve your product time-to-market and success rates, ultimately enabling overall product innovation performance to drive revenues.

Standardize and Automate Best Practices

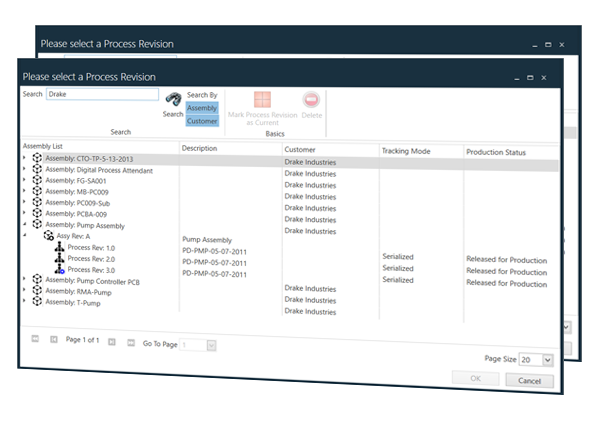

Easily automate single-piece flow, Engineer-to-Order (ETO), and Configure-to-Order (CTO) processes and reroutes while dynamically ensuring all documentation, revisions and instructions are up to date.

Streamline Data Preparation, Work Instruction Authoring, and Operator Enablement for Growth

Improve Customer Value and Satisfaction

Avoid Unexpected Costs

Accelerate Growth Opportunity

Eliminate Manual Errors

Eliminate Waste & Duplication

Hit Product Launch Dates Consistently

Some other clients we’ve helped