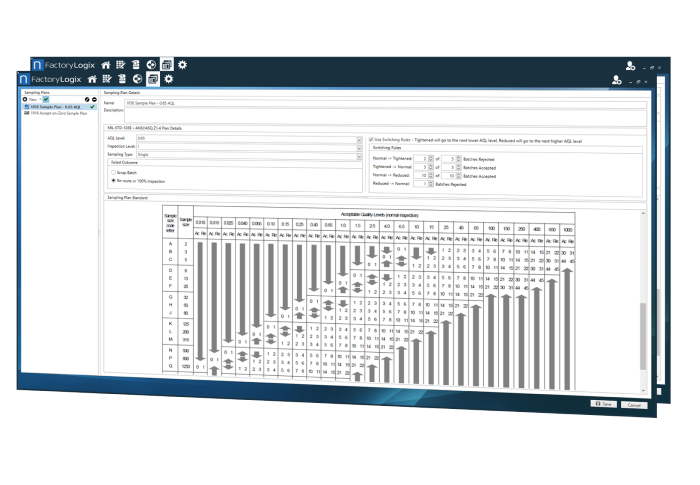

Increase Customer Satisfaction

Deliver zero-defect products, achieve optimal levels of customer satisfaction with QMS software.

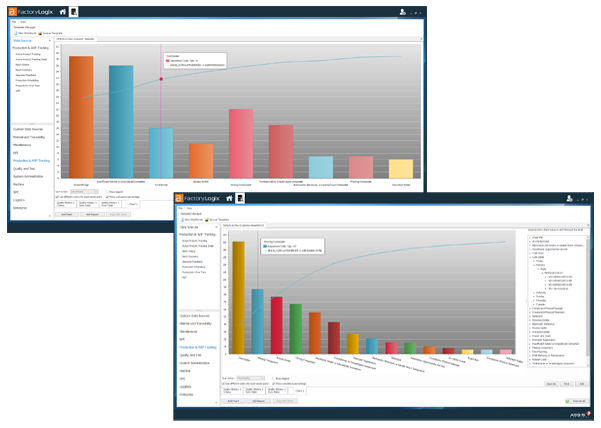

Reduce Cost of Quality

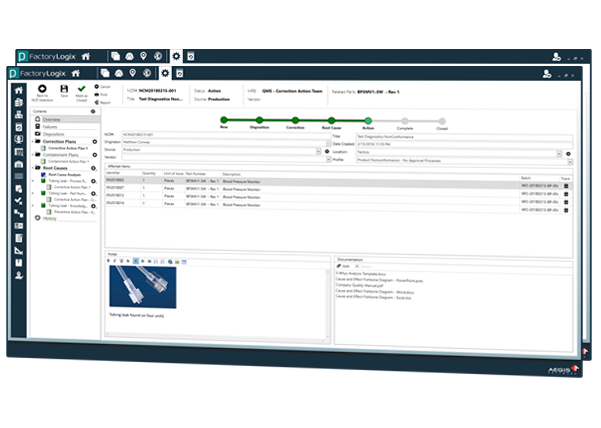

Automate quality processes and instantly access to actionable data.

Simplify Audits

Our quality control software for manufacturing is a single source of truth to simplify regulatory & customer compliance reporting.

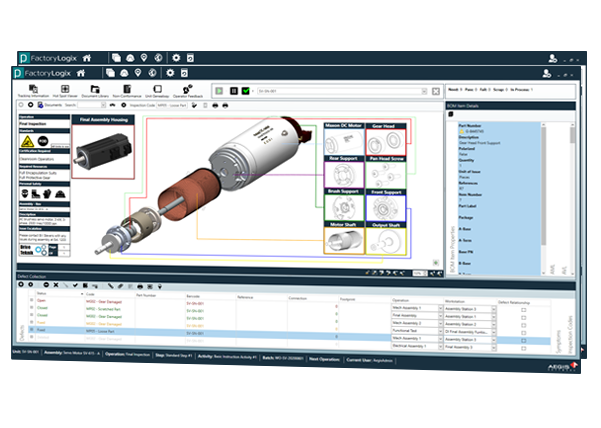

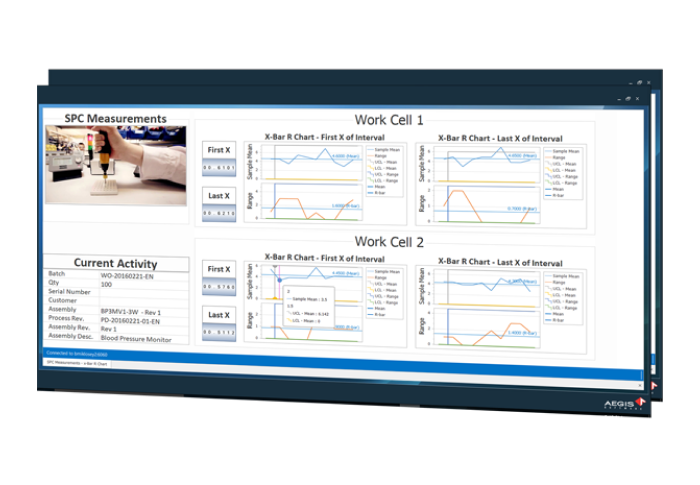

Automating Comprehensive Zero-Defect Quality

5% Reduction in Defective Parts Per Million (DPMO)

Improve First Pass Yield

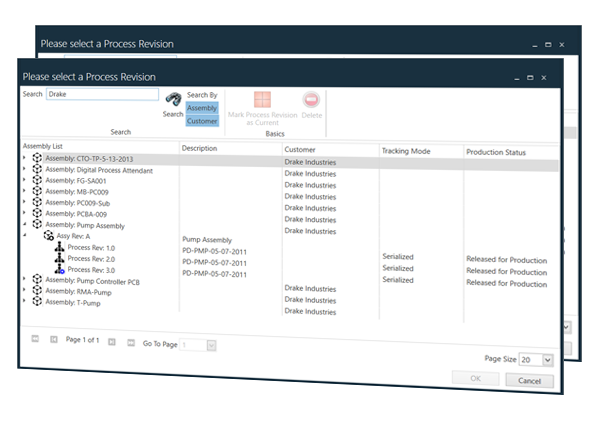

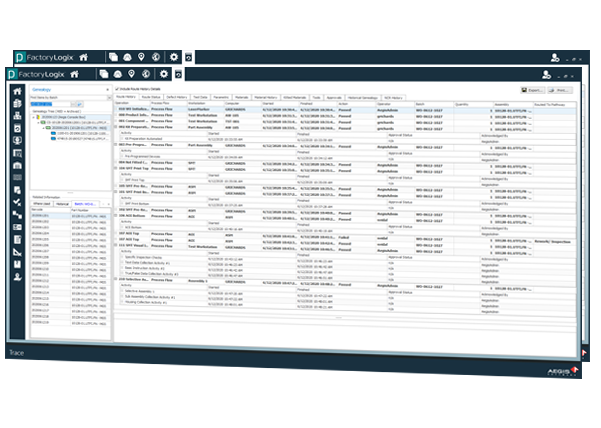

Achieve Level-4 Component Traceabiliy

Reduce Report Creation Time from Weeks to Real-Time

Reduce Assembly Rework Time by 30%

Improve Customer Response Times

SOME OTHER CLIENTS WE'VE HELPED