Reduce Costs

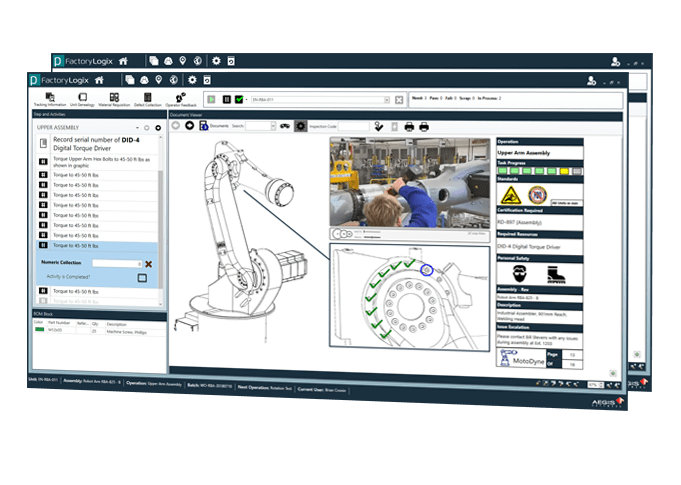

Improve operator productivity and job satisfaction, reduce scrap, waste, and cost of poor quality with manufacturing process execution software.

Achieve Process Excellence

Improve yield, and throughput, while facilitating continuous process assurance, conformance, and improvement.

Grow Revenues & Scale

Manufacturing assembly process software allows you to modernize operations, such that they easily scale and quickly adapt to dynamic conditions.

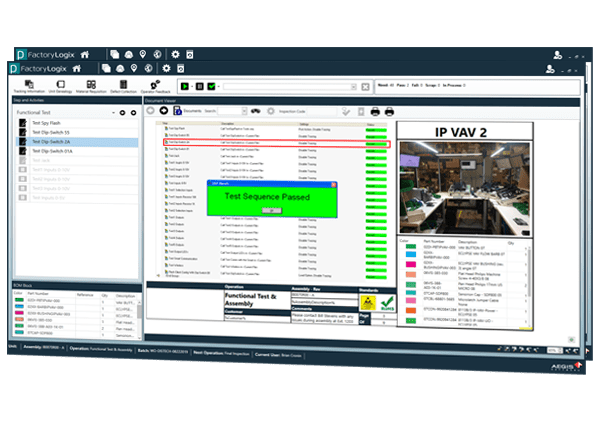

Achieve Next-Level Manufacturing Process Execution

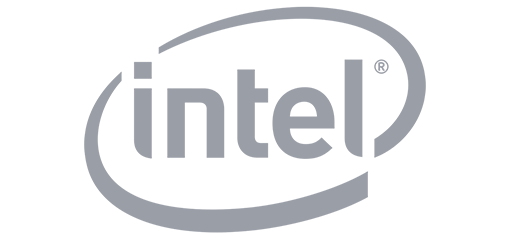

Reduce Unexpected Production Delays

Contextualize IIoT Data from Multiple, Fast-Changing Sources, Driving Optimization

Improve Agility & Flexibility

Resolve Bottlenecks, Imbalances & Process Starvation

Support Regulatory & Compliance Requirements

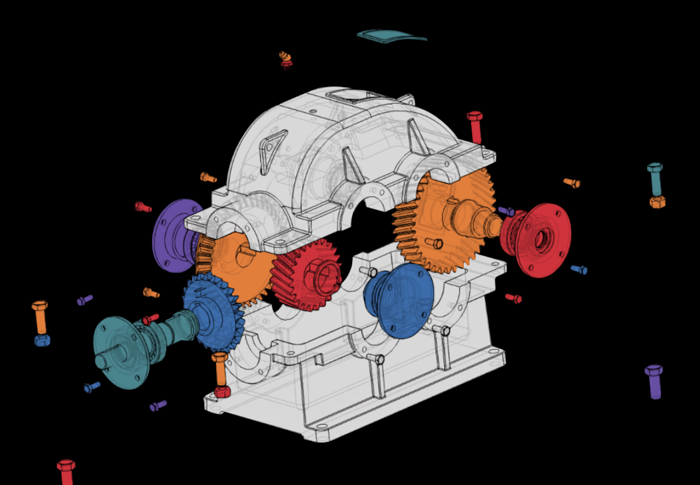

Eliminate Mistakes Due to Incorrect Routing/Sequencing

some other clients we’ve helped