Case Study: ADEX Electronique

Read in this Case Study about ADEX Electronique's challenges leading them to select the right MES solution, and how they are now achieving Industry 4.0 benefits, with FactoryLogix.

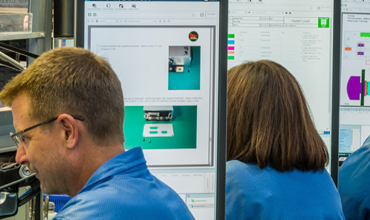

Case Study: Microboard Processing, Inc.

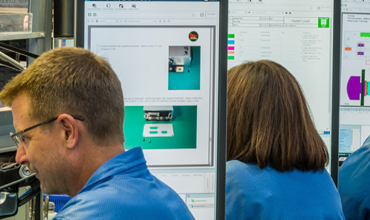

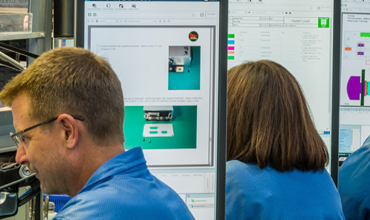

With a modern and intuitive user interface designed to run on today’s tablets and touchscreen displays, FactoryLogix® accommodates users of all skill levels, guiding them through operations in one simple interface.

Case Study: Connor Solutions

The implementation of Aegis’ FactoryLogix Software, has enabled significant new business opportunities for the company.

Case Study: Norautron Suzhou Co. Ltd.

Ever increasing customer requirements and market regulations for mission-critical products is the most important reasons why Norautron found their home-grown system no longer adequate.

Case Study: TBP Electronics

Aegis Software provides the digital framework that enables TBP to drive toward Industry 4.0 and “The Business of Perfection”.

Case Study: Cirtronics

Cirtronics improves productivity, reduces errors and eliminates waste by shortening the time to complete a key business process from hours to a matter of minutes.

Case Study: EPE

By implementing Aegis' MES, EPE now has world-class visibility and control without having the endless software customization and report development costs typical of other commercial MES systems.

Case Study: Sparton Corporation

As today’s regulatory requirements evolve, and customer demands for greater traceability follow suit, Sparton now has an easily-configurable system in place to quickly respond to these changes.

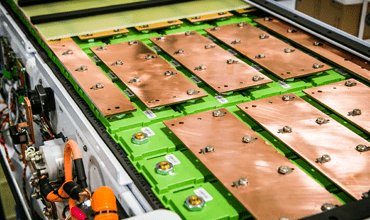

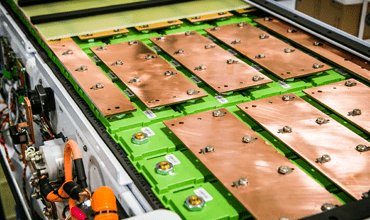

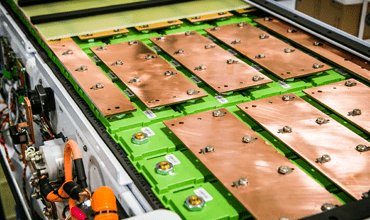

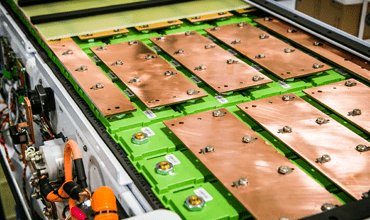

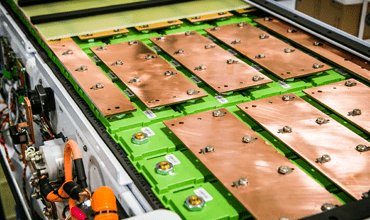

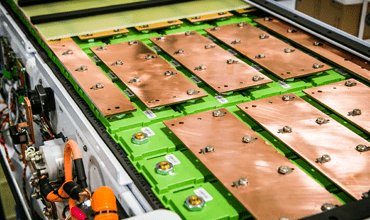

Case Study: K2 Energy

As manufacturers in the A&D space prepare their factories to comply with new industry regulations, quality control will remain paramount, as will the ability to adapt to technological innovation. Implementing an advanced MES solves control and flexibility challenges as well as enforces regulatory compliance.

Case Study: ADEX Electronique

Read in this Case Study about ADEX Electronique's challenges leading them to select the right MES solution, and how they are now achieving Industry 4.0 benefits, with FactoryLogix.

Case Study: Microboard Processing, Inc.

With a modern and intuitive user interface designed to run on today’s tablets and touchscreen displays, FactoryLogix® accommodates users of all skill levels, guiding them through operations in one simple interface.

Case Study: Connor Solutions

The implementation of Aegis’ FactoryLogix Software, has enabled significant new business opportunities for the company.

Case Study: Norautron Suzhou Co. Ltd.

Ever increasing customer requirements and market regulations for mission-critical products is the most important reasons why Norautron found their home-grown system no longer adequate.

Case Study: TBP Electronics

Aegis Software provides the digital framework that enables TBP to drive toward Industry 4.0 and “The Business of Perfection”.

Case Study: Cirtronics

Cirtronics improves productivity, reduces errors and eliminates waste by shortening the time to complete a key business process from hours to a matter of minutes.

Case Study: EPE

By implementing Aegis' MES, EPE now has world-class visibility and control without having the endless software customization and report development costs typical of other commercial MES systems.

Case Study: Sparton Corporation

As today’s regulatory requirements evolve, and customer demands for greater traceability follow suit, Sparton now has an easily-configurable system in place to quickly respond to these changes.

Case Study: K2 Energy

As manufacturers in the A&D space prepare their factories to comply with new industry regulations, quality control will remain paramount, as will the ability to adapt to technological innovation. Implementing an advanced MES solves control and flexibility challenges as well as enforces regulatory compliance.

Case Study: ADEX Electronique

Read in this Case Study about ADEX Electronique's challenges leading them to select the right MES solution, and how they are now achieving Industry 4.0 benefits, with FactoryLogix.

Case Study: Microboard Processing, Inc.

With a modern and intuitive user interface designed to run on today’s tablets and touchscreen displays, FactoryLogix® accommodates users of all skill levels, guiding them through operations in one simple interface.

Case Study: Connor Solutions

The implementation of Aegis’ FactoryLogix Software, has enabled significant new business opportunities for the company.

Case Study: Norautron Suzhou Co. Ltd.

Ever increasing customer requirements and market regulations for mission-critical products is the most important reasons why Norautron found their home-grown system no longer adequate.

Case Study: TBP Electronics

Aegis Software provides the digital framework that enables TBP to drive toward Industry 4.0 and “The Business of Perfection”.

Case Study: Cirtronics

Cirtronics improves productivity, reduces errors and eliminates waste by shortening the time to complete a key business process from hours to a matter of minutes.

Case Study: EPE

By implementing Aegis' MES, EPE now has world-class visibility and control without having the endless software customization and report development costs typical of other commercial MES systems.

Case Study: Sparton Corporation

As today’s regulatory requirements evolve, and customer demands for greater traceability follow suit, Sparton now has an easily-configurable system in place to quickly respond to these changes.

Case Study: K2 Energy

As manufacturers in the A&D space prepare their factories to comply with new industry regulations, quality control will remain paramount, as will the ability to adapt to technological innovation. Implementing an advanced MES solves control and flexibility challenges as well as enforces regulatory compliance.

Case Study: ADEX Electronique

Read in this Case Study about ADEX Electronique's challenges leading them to select the right MES solution, and how they are now achieving Industry 4.0 benefits, with FactoryLogix.

Case Study: Microboard Processing, Inc.

With a modern and intuitive user interface designed to run on today’s tablets and touchscreen displays, FactoryLogix® accommodates users of all skill levels, guiding them through operations in one simple interface.

Case Study: Connor Solutions

The implementation of Aegis’ FactoryLogix Software, has enabled significant new business opportunities for the company.

Case Study: Norautron Suzhou Co. Ltd.

Ever increasing customer requirements and market regulations for mission-critical products is the most important reasons why Norautron found their home-grown system no longer adequate.

Case Study: TBP Electronics

Aegis Software provides the digital framework that enables TBP to drive toward Industry 4.0 and “The Business of Perfection”.

Case Study: Cirtronics

Cirtronics improves productivity, reduces errors and eliminates waste by shortening the time to complete a key business process from hours to a matter of minutes.

Case Study: EPE

By implementing Aegis' MES, EPE now has world-class visibility and control without having the endless software customization and report development costs typical of other commercial MES systems.

Case Study: Sparton Corporation

As today’s regulatory requirements evolve, and customer demands for greater traceability follow suit, Sparton now has an easily-configurable system in place to quickly respond to these changes.

Case Study: K2 Energy

As manufacturers in the A&D space prepare their factories to comply with new industry regulations, quality control will remain paramount, as will the ability to adapt to technological innovation. Implementing an advanced MES solves control and flexibility challenges as well as enforces regulatory compliance.

Case Study: ADEX Electronique

Read in this Case Study about ADEX Electronique's challenges leading them to select the right MES solution, and how they are now achieving Industry 4.0 benefits, with FactoryLogix.

Case Study: Microboard Processing, Inc.

With a modern and intuitive user interface designed to run on today’s tablets and touchscreen displays, FactoryLogix® accommodates users of all skill levels, guiding them through operations in one simple interface.

Case Study: Connor Solutions

The implementation of Aegis’ FactoryLogix Software, has enabled significant new business opportunities for the company.

Case Study: Norautron Suzhou Co. Ltd.

Ever increasing customer requirements and market regulations for mission-critical products is the most important reasons why Norautron found their home-grown system no longer adequate.

Case Study: TBP Electronics

Aegis Software provides the digital framework that enables TBP to drive toward Industry 4.0 and “The Business of Perfection”.

Case Study: Cirtronics

Cirtronics improves productivity, reduces errors and eliminates waste by shortening the time to complete a key business process from hours to a matter of minutes.

Case Study: EPE

By implementing Aegis' MES, EPE now has world-class visibility and control without having the endless software customization and report development costs typical of other commercial MES systems.

Case Study: Sparton Corporation

As today’s regulatory requirements evolve, and customer demands for greater traceability follow suit, Sparton now has an easily-configurable system in place to quickly respond to these changes.

Case Study: K2 Energy

As manufacturers in the A&D space prepare their factories to comply with new industry regulations, quality control will remain paramount, as will the ability to adapt to technological innovation. Implementing an advanced MES solves control and flexibility challenges as well as enforces regulatory compliance.

Case Study: ADEX Electronique

Read in this Case Study about ADEX Electronique's challenges leading them to select the right MES solution, and how they are now achieving Industry 4.0 benefits, with FactoryLogix.

Case Study: Microboard Processing, Inc.

With a modern and intuitive user interface designed to run on today’s tablets and touchscreen displays, FactoryLogix® accommodates users of all skill levels, guiding them through operations in one simple interface.

Case Study: Connor Solutions

The implementation of Aegis’ FactoryLogix Software, has enabled significant new business opportunities for the company.

Case Study: Norautron Suzhou Co. Ltd.

Ever increasing customer requirements and market regulations for mission-critical products is the most important reasons why Norautron found their home-grown system no longer adequate.

Case Study: TBP Electronics

Aegis Software provides the digital framework that enables TBP to drive toward Industry 4.0 and “The Business of Perfection”.

Case Study: Cirtronics

Cirtronics improves productivity, reduces errors and eliminates waste by shortening the time to complete a key business process from hours to a matter of minutes.

Case Study: EPE

By implementing Aegis' MES, EPE now has world-class visibility and control without having the endless software customization and report development costs typical of other commercial MES systems.

Case Study: Sparton Corporation

As today’s regulatory requirements evolve, and customer demands for greater traceability follow suit, Sparton now has an easily-configurable system in place to quickly respond to these changes.

Case Study: K2 Energy

As manufacturers in the A&D space prepare their factories to comply with new industry regulations, quality control will remain paramount, as will the ability to adapt to technological innovation. Implementing an advanced MES solves control and flexibility challenges as well as enforces regulatory compliance.

Case Study: ADEX Electronique

Read in this Case Study about ADEX Electronique's challenges leading them to select the right MES solution, and how they are now achieving Industry 4.0 benefits, with FactoryLogix.

Case Study: Microboard Processing, Inc.

With a modern and intuitive user interface designed to run on today’s tablets and touchscreen displays, FactoryLogix® accommodates users of all skill levels, guiding them through operations in one simple interface.

Case Study: Connor Solutions

The implementation of Aegis’ FactoryLogix Software, has enabled significant new business opportunities for the company.

Case Study: Norautron Suzhou Co. Ltd.

Ever increasing customer requirements and market regulations for mission-critical products is the most important reasons why Norautron found their home-grown system no longer adequate.

Case Study: TBP Electronics

Aegis Software provides the digital framework that enables TBP to drive toward Industry 4.0 and “The Business of Perfection”.

Case Study: Cirtronics

Cirtronics improves productivity, reduces errors and eliminates waste by shortening the time to complete a key business process from hours to a matter of minutes.

Case Study: EPE

By implementing Aegis' MES, EPE now has world-class visibility and control without having the endless software customization and report development costs typical of other commercial MES systems.

Case Study: Sparton Corporation

As today’s regulatory requirements evolve, and customer demands for greater traceability follow suit, Sparton now has an easily-configurable system in place to quickly respond to these changes.

Case Study: K2 Energy

As manufacturers in the A&D space prepare their factories to comply with new industry regulations, quality control will remain paramount, as will the ability to adapt to technological innovation. Implementing an advanced MES solves control and flexibility challenges as well as enforces regulatory compliance.

Case Study: ADEX Electronique

Read in this Case Study about ADEX Electronique's challenges leading them to select the right MES solution, and how they are now achieving Industry 4.0 benefits, with FactoryLogix.

Case Study: Microboard Processing, Inc.

With a modern and intuitive user interface designed to run on today’s tablets and touchscreen displays, FactoryLogix® accommodates users of all skill levels, guiding them through operations in one simple interface.

Case Study: Connor Solutions

The implementation of Aegis’ FactoryLogix Software, has enabled significant new business opportunities for the company.

Case Study: Norautron Suzhou Co. Ltd.

Ever increasing customer requirements and market regulations for mission-critical products is the most important reasons why Norautron found their home-grown system no longer adequate.

Case Study: TBP Electronics

Aegis Software provides the digital framework that enables TBP to drive toward Industry 4.0 and “The Business of Perfection”.

Case Study: Cirtronics

Cirtronics improves productivity, reduces errors and eliminates waste by shortening the time to complete a key business process from hours to a matter of minutes.

Case Study: EPE

By implementing Aegis' MES, EPE now has world-class visibility and control without having the endless software customization and report development costs typical of other commercial MES systems.

Case Study: Sparton Corporation

As today’s regulatory requirements evolve, and customer demands for greater traceability follow suit, Sparton now has an easily-configurable system in place to quickly respond to these changes.

Case Study: K2 Energy

As manufacturers in the A&D space prepare their factories to comply with new industry regulations, quality control will remain paramount, as will the ability to adapt to technological innovation. Implementing an advanced MES solves control and flexibility challenges as well as enforces regulatory compliance.

Case Study: ADEX Electronique

Read in this Case Study about ADEX Electronique's challenges leading them to select the right MES solution, and how they are now achieving Industry 4.0 benefits, with FactoryLogix.

Case Study: Microboard Processing, Inc.

With a modern and intuitive user interface designed to run on today’s tablets and touchscreen displays, FactoryLogix® accommodates users of all skill levels, guiding them through operations in one simple interface.

Case Study: Connor Solutions

The implementation of Aegis’ FactoryLogix Software, has enabled significant new business opportunities for the company.

Case Study: Norautron Suzhou Co. Ltd.

Ever increasing customer requirements and market regulations for mission-critical products is the most important reasons why Norautron found their home-grown system no longer adequate.

Case Study: TBP Electronics

Aegis Software provides the digital framework that enables TBP to drive toward Industry 4.0 and “The Business of Perfection”.

Case Study: Cirtronics

Cirtronics improves productivity, reduces errors and eliminates waste by shortening the time to complete a key business process from hours to a matter of minutes.

Case Study: EPE

By implementing Aegis' MES, EPE now has world-class visibility and control without having the endless software customization and report development costs typical of other commercial MES systems.

Case Study: Sparton Corporation

As today’s regulatory requirements evolve, and customer demands for greater traceability follow suit, Sparton now has an easily-configurable system in place to quickly respond to these changes.

Case Study: K2 Energy

As manufacturers in the A&D space prepare their factories to comply with new industry regulations, quality control will remain paramount, as will the ability to adapt to technological innovation. Implementing an advanced MES solves control and flexibility challenges as well as enforces regulatory compliance.

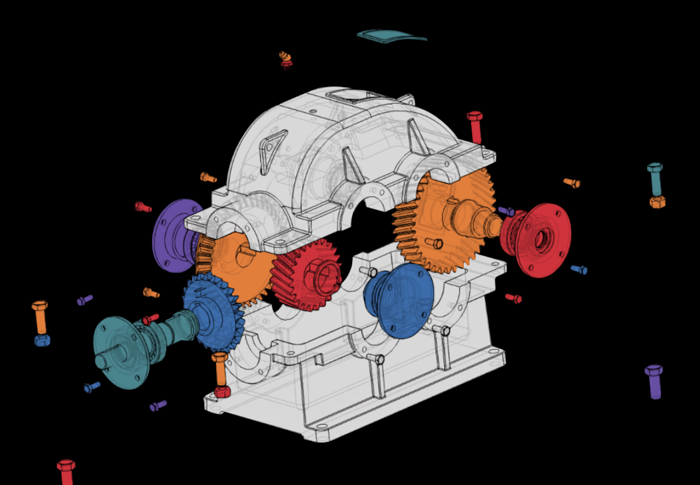

Unleash the Power of 3D CAD in FactoryLogix

FactoryLogix brings the actual 3D design of mechanical parts and assemblies directly to the operators, bridging both electronic and mechanical design in one thread to the shop floor. Accelerate assembly and inspection, enrich operator experience, reduce errors, and speed time to market—from the PCB to the final product, no matter what you are building!

Manufacturing Excellence Digitized

Aegis’ FactoryLogix provides everything you need to achieve the speed, agility, visibility, and control required by today’s industrial landscape. Enhance your competitive advantage and accelerate digital transformation with a uniquely adaptive manufacturing platform.

FactoryOptix: Augmented Reality Video

FactoryOptix is a unique technology that integrates human assembly operations directly into the automated Industry 4.0 environment, using Augmented Reality as a built-in extension to FactoryLogix paperless work-instructions.

Unleash the Power of 3D CAD in FactoryLogix

FactoryLogix brings the actual 3D design of mechanical parts and assemblies directly to the operators, bridging both electronic and mechanical design in one thread to the shop floor. Accelerate assembly and inspection, enrich operator experience, reduce errors, and speed time to market—from the PCB to the final product, no matter what you are building!

Dynamic, Interactive Visual Work Instructions

By adopting a true paperless environment, and not just displaying PDFs, videos and images, a factory can increase yields, quality and traceability while reducing costs and eliminating risks.

FactoryLogix: Process Engineering

Engineers define the process, not the physical route, permitting for total freedom to apply the assembly process across disparate assembly lines where station counts vary and operations may be performed by a human or by machine.

FactoryLogix: Analytics

Empowering manufacturing and operations personnel to perform data retrievals in a simple and straightforward manner. Enabling any user to retrieve, filter, sort, group, and even export the vast store of data within the Aegis system entirely graphically—no SQL, scripting, or IT knowledge necessary.

FactoryLogix: Overview

FactoryLogix is an integrated suite of software modules and devices that bring speed, control, and visibility to your manufacturing operations, ultimately saving time, reducing cost and risk, and resulting in increased business opportunity.

FactoryLogix: Configuration vs. Coding

FactoryLogix offers a new and refreshing approach where the system administrators simply configure most every aspect of the user experience through graphical interfaces and wizards.

FactoryLogix: Traceability

Reduce In-Process Costs - Eliminate Recalls - Meet Regulatory Requirements.