Manufacturers have been told for years that data is their greatest untapped resource. But for many, the promise of turning raw information into real insight still feels out of reach. The systems may be in place such as ERP, MES, quality, and more but what is the payoff? Often underwhelming.

Most manufacturers aren’t struggling with a lack of data. The bigger issue is figuring out what to do with it, and how to make it useful in time to drive decisions. A recent survey of over 400 global manufacturers, conducted by Tech-Clarity and MESA International, makes this clear. More than half said their data is unreliable or inconsistent. Many cited difficulties accessing data when they needed it. And others pointed out that, even when the numbers are available, they aren’t presented in a way that helps anyone on the shop floor take action.

This isn’t a good place to be. Especially now, when every minute of downtime or missed insight can mean lost revenue or a dissatisfied customer.

Why Manufacturers Still Struggle with Data

These are long-standing problems. Most factories already have systems to track performance and quality, but that doesn’t mean the data is usable or trusted.

When data isn’t tied to the right machine, operator, or product version, it quickly loses meaning. And when different systems present conflicting views, trust in the data—and in the insights it’s meant to provide—begins to erode. But the real challenge goes even deeper. Most of the time, it’s not immediately clear what you should even be looking for in a dataset until you can see how all the pieces fit together. That’s why context is everything. To truly understand what’s happening, data needs to reflect the full picture: product design and configuration, process steps, personnel, equipment, materials consumed, automation events, and more. Only when these elements are meaningfully connected can the true nature of an issue—or opportunity—emerge from the data.

Top-performing manufacturers take a different approach. They build context into their data from the beginning. That means capturing process events, quality results, and changes in real time and contextualizing that data by tying it not just to a specific work order, but also to the associated product design & configuration, process steps, equipment, materials consumed, and people involved at each stage.

Some Manufacturing Operations Software solutions don’t just structure data—they contextualize it as it's created. Every data point is automatically linked to the right product, process, equipment, operator, and step in the workflow. And not just loosely connected—production context variables and quality results can be intrinsically tied all the way down to individual attributes within a specific part in the CAD design model. This level of built-in context removes the need to stitch together information from separate systems and ensures that insights are accurate, meaningful, and available exactly when and where they’re needed.

What Top Performers Are Doing Differently

The survey also revealed what separates top-performing manufacturers from the rest. These companies outperform their peers in areas like first-pass yield, OEE, and on-time delivery. But it’s not just about having better tools. It’s about how they use them.

Top performers:

- Use dashboards designed for operations teams, not just executives

- Apply predictive analytics to avoid issues instead of just explaining them

- Keep process data and product data connected from end-to-end

- Emphasize data governance to ensure consistency and trust

And more importantly, they understand that analytics only work if the underlying data is accurate and timely.

What sets these top performers apart isn’t just access to data it’s how that data is contextualized and governed from the ground up. Rather than relying on siloed reports or batch-level summaries, they generate insights directly from live production data tied to real processes. This lets them identify problems earlier, make necessary adjustments faster, and continuously improve with confidence.

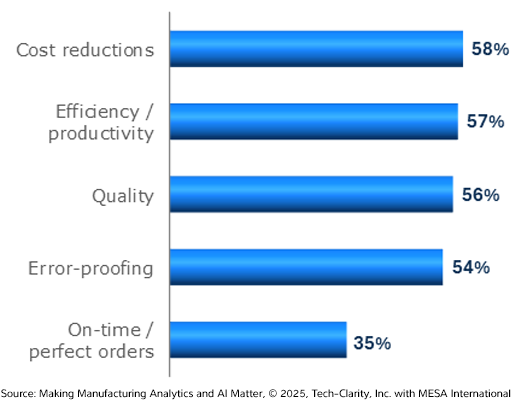

Not surprisingly, these data-driven habits translate directly into measurable business results. When asked where analytics are having the greatest impact, manufacturers pointed to the following areas:

Top Areas That Benefit Significantly from Analytics

Cost reduction led the way, followed closely by improvements in efficiency, quality, and error-proofing. These are exactly the kinds of outcomes possible when manufacturers move beyond surface-level reports and start using insights to guide day-to-day execution.

Turning Insights into Real Business Value

Once the right data is in the right hands, the impact is immediate.

Cost reduction was the top benefit reported. That’s no surprise that data helps identify waste in processes, materials, and labor. But there’s more to it. Productivity improves because operators and supervisors no longer waste time searching for information or reacting to last-minute surprises.

AI-driven quality analysis can detect early warning signs based on patterns from past runs. That information enables teams to intervene before a defect impacts an entire batch. Customer complaints go down, and first-pass yield improves.

Decisions also get faster. Instead of waiting for a weekly report, production leaders can adjust during the shift based on what’s actually happening. But again, none of this is possible without a solid data foundation. That’s why manufacturers using contextual MES platforms, like FactoryLogix, have a head start. These systems connect everything from engineering to execution to quality, giving teams a shared source of truth.

The Hidden Roadblock: Inconsistent and Unreliable Data

Analytics and AI are only as strong as the data they rely upon. Yet, most manufacturers are still dealing with inconsistent, unreliable, or siloed data that weakens even the most advanced digital initiatives.

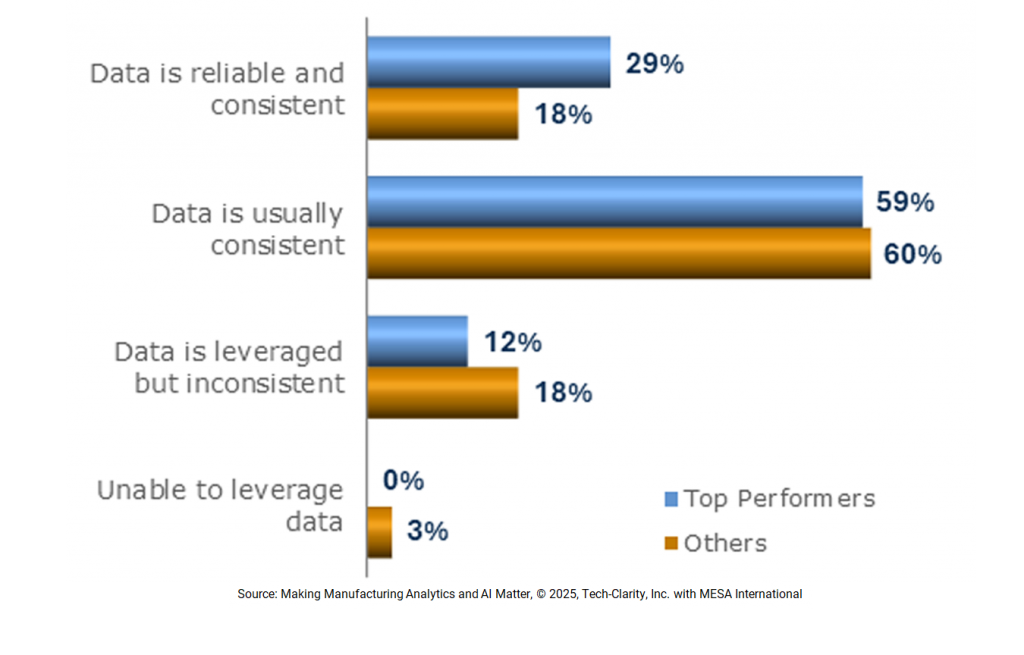

Maturity of Manufacturing Dataops

According to the study, only 29% of Top Performers and 18% of Others say their data is reliable and consistent. While most say their data is “usually consistent,” the report points out that even that isn’t enough. For analytics and AI to drive decisions on the shop floor, the data behind those insights must be accurate, timely, and trusted not "good enough."

Another issue is the lack of seamless data movement within operations. Just 38% of Top Performers say they’re good at moving operational data without manual steps, and the number drops even further for everyone else. These breaks in data flow add friction, reduce visibility, and slow down decision-making when speed matters most.

The report suggests a more pragmatic approach: start small. Instead of aiming to fix all data at once, focus on making specific data sets consistent, usable, and well-governed within the context of a particular initiative. That’s often enough to get value from analytics right away and it sets the stage for broader improvements later.

This is where systems like FactoryLogix play a key role. With a fully unified and contextualized data model, FactoryLogix captures and connects design data, processes, product, people, and machine data from the start. That kind of built-in structure helps teams trust the data they’re working with. It’s already tied to what’s happening on the shop floor, so they don’t have to second-guess it or spend time cleaning it up before using it.

Moving from Reaction to Prediction

More manufacturers are trying to get ahead of problems instead of reacting to them after the fact. They’re starting to use real-time alerts, machine learning, and trend analysis to spot issues before they turn into bigger problems. But these tools only work when they’re built on trustworthy, high-quality data.

Top manufacturers are using:

- Machine learning to predict performance dips or equipment failures

- Real-time analytics to proactively adjust schedules, rebalance workloads, or reroute production to available resources

However, 70% of companies say they don’t have enough clean data to make predictive models work. That means the barrier isn’t the algorithm, it’s the input.

If your system captures and contextualizes process steps, inspection results, operator decisions, and machine data together, then AI can start to see the full picture. But if your data is fragmented, even the best AI model won’t help.

Predictive tools perform best when built on systems that capture consistent, contextualized data from the beginning not patched together after the fact.

Generative AI on the Factory Floor

Generative AI is starting to make its way into operations, but not in the way most people think. It’s not about flashy but low-utility features like a clever shop floor chatbot—it’s about helping people do their jobs better with faster access to relevant insights and guidance.

Manufacturers are exploring GenAI to:

- Help new workers access tribal knowledge without needing to call for help

- Summarize production and quality data to automatically generate shift overviews, inspection highlights, and other operational reports

- Recommend corrective actions or process adjustments based on patterns in historical data

But GenAI only works well if the data it draws from is already structured and trustworthy. If documents are outdated or disconnected from execution data, then AI won’t deliver helpful results.

Platforms like FactoryLogix, where all production and quality data are unified and contextualized, make GenAI much more useful. Operators and engineers can get relevant guidance without digging through PDFs or waiting for reports.

Final Thoughts

Manufacturing analytics and AI don’t succeed because of flashy features. They succeed when they’re built on a strong foundation of structured, contextual, and trusted data.

The companies making the most of these technologies are the ones who’ve taken the time to align tools with processes. They’re not just visualizing data they’re acting on it. They’ve made analytics part of daily operations, not just a monthly dashboard.

As a starting point, consider these questions:

- Is our data tied to actual events, products, and processes or is it disconnected and difficult to trust?

- Can our operators and engineers act on insights in real time, or are they stuck reacting after the fact?

- Are we just reviewing past reports, or are we using live data to continuously learn and improve?

If the answers reveal gaps, start with the data. Look for solutions that build in structure, provide context, and make information accessible to the people closest to the process so decisions can be made with confidence, not guesswork. When you do, analytics stop being a reporting tool and start becoming a competitive edge.

For deeper insights on how top manufacturers are turning data into action, access the full Tech-Clarity & MESA International report here: 👉 Making Manufacturing Analytics & AI Matter

Sign up for our blog

Stay up-to-date on the latest in manufacturing trends, insights and best practices.