How Aegis’ FactoryLogix platform can help manufacturers transform their operations and achieve Industry 4.0 benefits

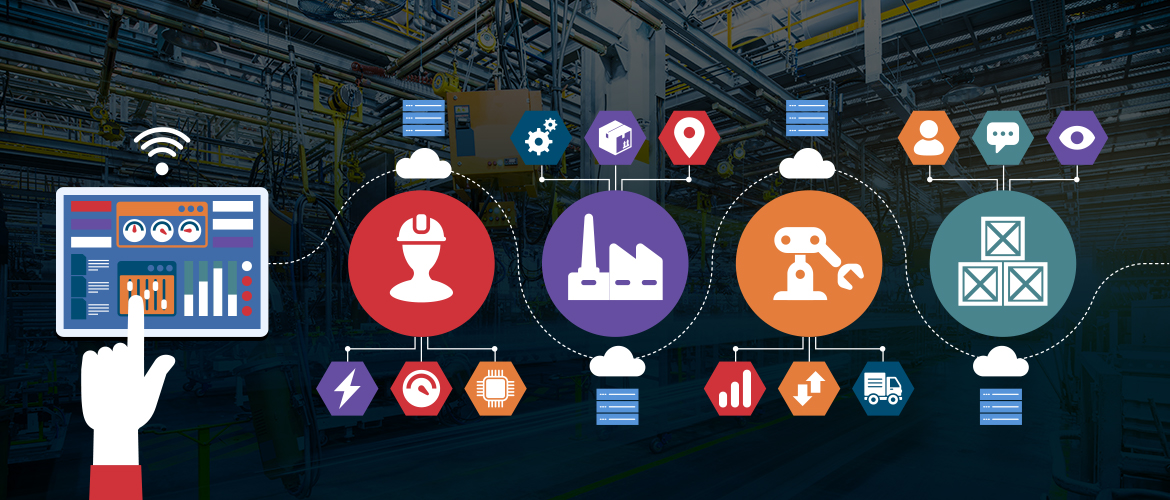

Smart Industry 4.0 applications are revolutionizing manufacturing processes today by bridging the gap between high-level Information Technology and floor-level Operational Technology—all while leveraging intelligent data insights to power factory-wide analytics. To be successful, Industry 4.0 needs to be embraced by manufacturers as a long-term, strategic mindset of digital transformation that can dynamically revolutionize their operational perspectives.

Dorigo Systems, a Canadian electronics manufacturing services company, embraced this concept as they planned the building of their new facility in 2018. The organization’s goals were to create a new manufacturing space with the flexibility for future growth and design an infrastructure that would inspire new levels of productivity. To support its vision for digital transformation, Dorigo Systems turned to Aegis. Let’s explore some of the ways Aegis helped Dorigo Systems meet its goals:

Goal #1: Create a Seamless and Transparent Manufacturing Experience

Paramount to Dorigo Systems is its commitment to providing customers with a seamless and transparent manufacturing experience—from quote request through final delivery. The team determined that its new state-of-the-art facility—supported by Industry 4.0-connected communications—would significantly boost productivity, reduce costs, and improve product quality. Dorigo recognized that the way forward was viewing Industry 4.0 not as an endpoint—but rather as a journey. Aegis Software would support Dorigo in making this journey more efficient and successful.

Dorigo utilized Aegis’ FactoryLogix Manufacturing Execution System (MES) to increase productivity, efficiency, and operational success. Factories that have Industry 4.0 capabilities can shift their operations quickly, flexibly adapt to meet changing customer demands, enhance productivity, reduce waste, and accelerate production. With a solution like FactoryLogix, production plants can maintain better relationships with customers and supply chain partners, achieving an agile, flexible model for mass customization.

Goal #2: Control Materials Flow to Eliminate Downtime

Industry 4.0 automatically controls materials flow to eliminate downtime and operate at the lowest level of inventory possible. The ultimate objective is to transform manufacturing into an environment that is both adaptive and customer-centric. FactoryLogix enables Dorigo to oversee production at every step in the manufacturing process, continually improving quality and on-time delivery for every product built while simultaneously eliminating waste.

Goal #3: Ensure Smart, Connected Manufacturing Operations

A connected factory ecosystem is driven primarily by a unified view of the enterprises’ strategies and operations. With enhanced visibility and real-time data sharing, Dorigo’s connected Industry 4.0 ecosystem creates a two-way system of information sharing that ensures operations adhere to factory requirements and accurate operating protocols.

FactoryLogix gives the team the ability to communicate and display complex processes in a simplified format, with the agility and traceability to connect engineers with the manufacturing floor seamlessly. Through intuitive interfaces, contextual awareness, interactive work instructions, voice and gesture capabilities, and dynamic alerts—all powered and enhanced by Aegis’ data-sharing—Dorigo Systems can train employees easily while also improving the employee experience.

Goal #4: Increase Quality Standards at Every Step

FactoryLogix provides tight control and traceability, ensuring a quality production process at every step. Dorigo Systems uses the platform to oversee, monitor, and implement quality throughout the organization. The system manages the more obvious parts of quality such as inspection, diagnostics and repair, but also. assures each station’s materials and equipment are up to the necessary standards for specific products.

An example at an operator station: when a station is set up, it’s checked to ensure it’s not using an obsolete revision, the wrong tooling, expired materials or even if the operator is not adequately trained. This is done automatically by FactoryLogix, which reports back to Dorigo’s engineering team with dashboard summaries. The team can also validate operator training to ensure workers are certified to operate a specific machine and determine if they require retraining.

Goal #5: Leverage Specialized Insight for Team-Wide Flexibility

MES empowers operators to leverage specialized manufacturing insight without taking excessive time for cross-training—quickly establishing a high level of team-wide flexibility. The FactoryLogix system integrates all of the necessary functionality to easily standardize work instruction templates, operator interface templates, and quality plans and processes. As a result, the onboarding of new projects has been drastically expedited, as the software guides the team to the right decisions.

Enabling Industry 4.0 requires manufacturers to make sense of new IIoT analytics. The FactoryLogix xLink IIoT machine and device adapters transmit data from various factory resources to be easily viewed in the FactoryLogix system—making manually managed data, missing products, and unclear statuses a thing of the past.

By implementing Industry 4.0 Big Data, Machine Learning, and AI, Dorigo Systems can now optimize and simulate operational excellence, power new perspectives for statistical process control and business management, and utilize predictive and prescriptive insights to set objectives that deliver value.

The Future of Manufacturing, Enabled by Aegis

Aegis’ FactoryLogix combines system consolidation with seamless integration to simplify and streamline manufacturing processes. Its integrated platform of adaptable, state-of-the-art software modules support any form of discrete manufacturing without customization, providing Dorigo Systems—and other companies like it—the tools they need to improve every aspect of their operations and enable Industry 4.0 benefits.

While embracing digital transformation does not occur overnight, Dorigo Systems is an example of how Industry 4.0 can be achieved over time. Dorigo began its digital transformation and Industry 4.0 manufacturing journey strategically, then worked its way to development and implementation and is now primed for continued success.

Read original article here: Reaping the Benefits of the Connected Factory as published in PLANT Magazine

Sign up for our blog

Stay up-to-date on the latest in manufacturing trends, insights and best practices.